-

Pressure Pipe Flux Cored Wire CO2 Gas Shielded Welding

Flux cored wire CO2 gas shielded welding is becoming more and more popular. FCAW is also common in pressure vessels or pressure pipes, but there is a lot of controversy both in terms of experience and theory.

-

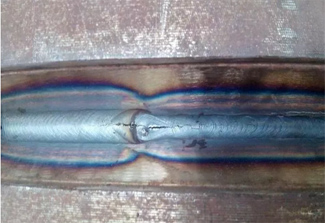

Take You Through The Cracks In The Weld

After the welding process or welding, metal cracking occurs in the welding area, which occurs inside or outside the weld, and may also occur in the heat affected zone.

-

What Is Slag Inclusion And Weld Slag

Non-metallic inclusions such as oxides, nitrides, sulfides, phosphides, etc. are found in the weld by non-destructive testing, forming a variety of irregular shapes, and common slag inclusions such as cones and needles

-

Arc pit Caused By Welding

The arc pit is a phenomenon that the welder machine at the end of the weld, which not only weakens the weld strength, but also causes cracks during the cooling process.

-

Weld Size Does Not Meet The Specification Requirements

Welding methods include: tungsten inert gas welding, TIG welding, manual welding, automatic welding, etc.

-

Comparison Of MIG Welding And TIG Welding(2)

TIG welding (Tungsten Inert Gas Welding), also known as non-melting inert gas tungsten welding. TIG welding is the most commonly used welding method, whether it is manual welding or automatic welding of stainless steel of 0.5 to 4.0 mm thickness.

-

Comparison Of MIG Welding And TIG Welding(1)

-

What Is Manual Arc Welding

-

The Welding Difference of TIG, MIG and MAG

-

How To Choose A Suitable Welding Machine (2)

-

How To Choose A Suitable Welding Machine (1)

-

The Features Of Mini Welder