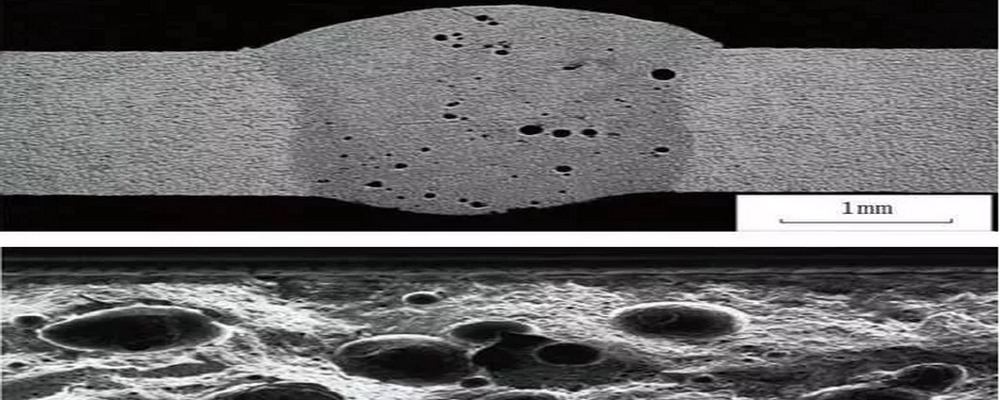

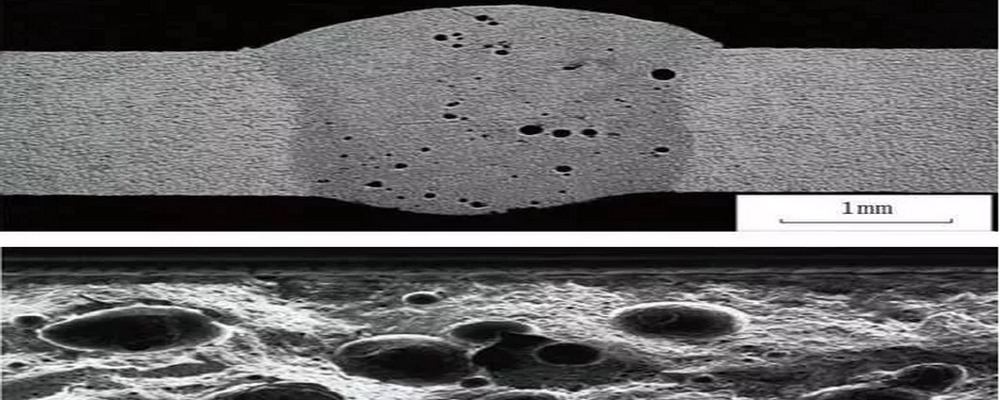

Understand The Pores In The Welding Process

Phenomenon: The gas absorbed in the weld metal melted during the welding process cannot be discharged from the molten pool before cooling, and remains in the weld to form a cavity. According to the position of the pores, the inner and outer pores can be divided. According to the condition and shape of the pores, the presence of the pores in the weld will reduce the weld strength, stress concentration, and low temperature brittleness and hot cracking tendency.

Reason: The welding rod itself is inferior, the welding rod is not dampened according to the requirements; the electrode strip is deteriorated or peeled off; the core is corroded. There is residual gas in the base metal smelting; the welding rod and the weldment are contaminated with impurities such as rust and oil, and gas is generated by high-temperature gasification during the welding process.

The welder's operating technique is unskilled, or the poor vision is unclear to the molten iron and the coating, so that the gas in the coating is mixed with the metal solution. If the welding current is too large, the welding rod will be reddish to reduce the protection effect; the arc length is too long; the power supply voltage fluctuates too much, causing unstable arc burning.

Control Measures: Select qualified welding rods, and do not use welding rods with cracked, peeled, deteriorated, eccentric or severely corroded cores. Clean oil and rust spots near the welds and on the surface of the welding rods. The size of the current should be chosen to control the welding speed. Before the welding, the workpiece is preheated. When the welding is finished or stopped in the middle, the arc should be slowly evacuated, which is beneficial to slow down the cooling rate of the molten pool and the gas in the molten pool to avoid the occurrence of porosity defects. Reduce the humidity at the welding operation site and increase the temperature of the operating environment. In outdoor welding, if the wind speed reaches 8m/s, rainfall, dew, snow, etc., it is necessary to take effective measures such as windshield and rain canopy before welding.